Type and hit enter

ACM Panels

Manaco offers high-quality aluminum composite material panels (ACM panels) operational for Toronto residential, and commercial buildings. Our aluminum panel guarantee long-lasting and strong finishing to enhance building appearance and design.

Request a call back

Need help with ACM design or contracting a new project? Please fill the form below and our team will get back to you in no time.

Overview

What is ACM Panels?

ACM Panels (Aluminum Composite Material Panels) are a unique building material. These panels consist of two aluminum layers coated with a core of non-aluminum metal plate. Aluminum panel is a high-end material that is strong and lasts longer. It offers the best weather resistance and is perfect for modern buildings. Due to these reasons, ACM panels remain very popular in contemporary buildings, especially for high-rise structures, because they have a long-lasting, beautiful, durable, and smooth appearance.

Advantages

Why Choose ACM Panels?

ACM panels are widely used due to their thin aluminum sheet construction, lightweight design, and availability in a variety of attractive colors.

So, these aluminum sheet metal materials are suitable for different applications, including building re-siding to beautifying and even high rises.

1

Rigidity and Lightness of ACM Composite Panels

Thanks to Aluminum Composite Material (ACM) panels, people can now utilize durable materials without the hassle of extra weight during shipping, loading, or installation, making the entire process significantly easier.

2

Aesthetic Versatility of ACM Composite Panels

ACM Panels are available in various colors and finishes that enable them to replicate materials like stone and wood, thus providing diversity in design. If you need aluminum panel or aluminum composite material cladding for your design, these materials are aesthetically versatile and durable.

3

Durability & Weathering Properties of ACM Panels

Prefinished ACM panels (ACP Aluminium Panel) are known for their UV, corrosion, and environmental exposure protection. Thanks to their sandwiched construction, aluminum composite materials are designed for long-term durability, making them an ideal choice for the exterior walls of aluminum buildings.

4

Cost-Effectiveness of ACM Composite Panels

Aluminum Composite Material panels provide an ideal building solution as they offer minimal maintenance and a high rate of production. They have good resistance to UV, corrosion, and wear by the environment. Also, aluminum steel sheets can serve for a very long time and are the best selection in the construction and interior field.

Project Types

Residential ACM Panels

ACM panels are also known as Aluminum Composite panels (ACP), which replace traditional materials that require regular maintenance. They are the ideal choice for those seeking a beautiful home that doesn’t demand frequent maintenance.

The type of aluminum composite material cladding contains various shades and finishes designed to give a wood, stone, or metal effect, regardless of the texture. By using ACM panels, renovating any house to achieve a presentable, stylish appearance while maintaining its form and aesthetics becomes much easier.

Project Types

Commercial ACM Cladding Solutions

Aluminum composite materials (ACM) offer functional benefits and enhanced architectural appeal, making them an ideal choice for corporate structures. Thanks to the robust nature of aluminum composite materials, they provide reliable protection against all weather conditions.

Due to its minimalistic sophisticated design, this enhances the professional status of a building. For places such as offices, retail zones, and showrooms, the ACM panels are the best to create high-quality looks for clients and potential customers.

Other Project Types

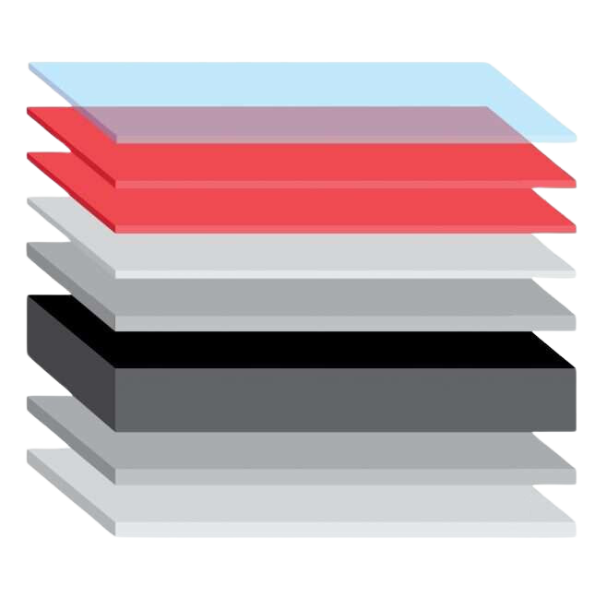

Top Layer

Clear Top UV Coat

Layer #2

Light Coating

Layer #3

Face Coating

Layer #4

Primer

Layer #5

0.5 mm Aluminum

Core

Polyethylene (PE) or fire-resistant material

Layer #6

0.5 mm Aluminum

Bottom Layer

Anti-corrosive Coating

Specifications

ACM Layers

Top Layer

Clear Top UV Coat

Layer #2

Light Coating

Layer #3

Face Coating

Layer #4

Primer

Layer #5

0.5 mm Aluminum

Core

Polyethylene (PE) or fire-resistant material

Layer #6

0.5 mm Aluminum

Bottom Layer

Anti-corrosive Coating

Specifications

ACM Specifications

You can find the below list of all the features that our product ranges cover in these fields: Atomic. Aluminum composite materials are constructed using the sandwich method, where two aluminum sheets, known as aluminum skins, are bonded to a core of low-density polyethylene (LDPE). You can order different ACM Panel Sizes based on your project requirements.

Panel Thickness

3mm - 6mm

Core Material

PE or FR Core

Finish Options

Gloss, Matte, Brushed

B1, A2

Durability

UV, weather, corrosion resistant

Weight

Approximately 9.8 kg/m²

Width

1220mm, 1250mm, 1500mm

Aluminum Skin Thickness

0.21mm - 0.5mm

Sound Insulation

Rw 25 dB

Thermal Expansion

2.4 mm/m at 100°C temperature change

Specifications

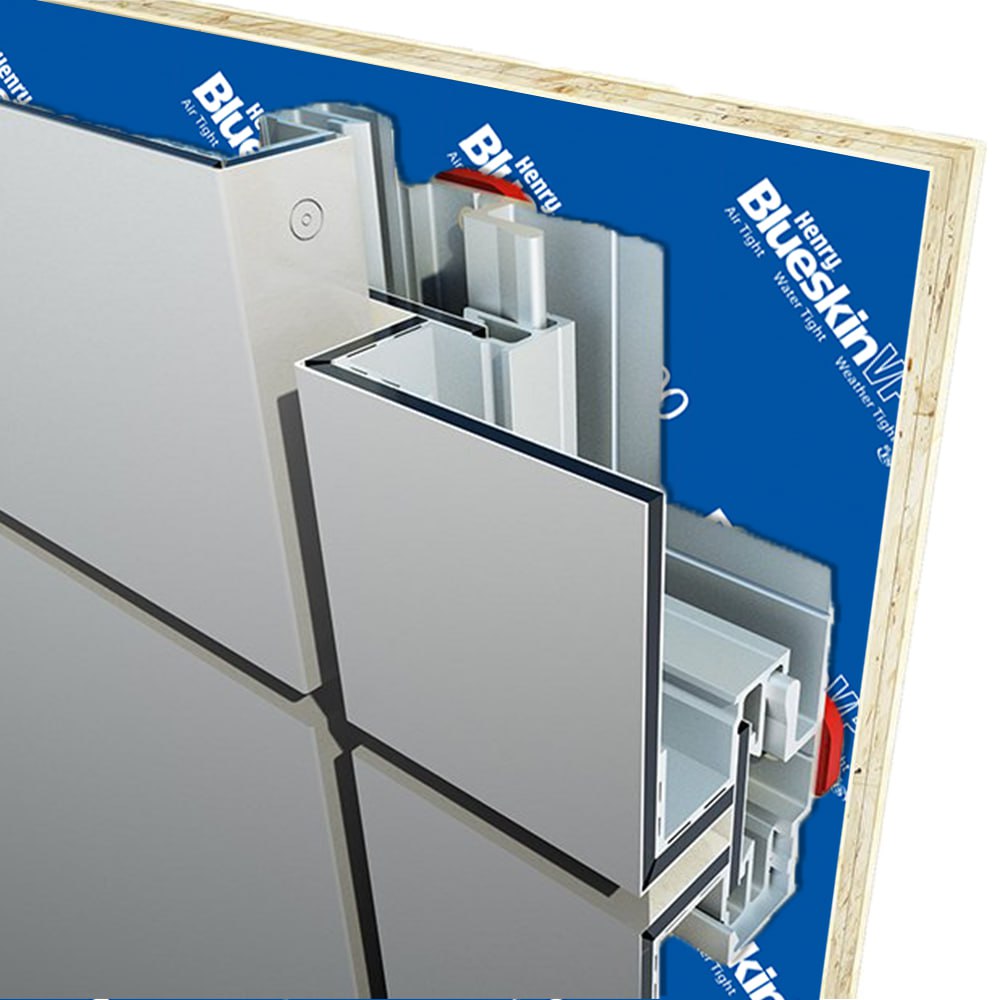

Mounting Systems

At Manaco Cladding, we offer a range of advanced installation systems for ACM cladding, ensuring precision, durability, and aesthetic excellence in every project. Here are the primary systems we use:

Hanging Systems

The suspension system is an adaptable system that uses proprietary spacers or shims, clips, addon frame holding profiles (E bars), and Z bars if necessary. ACM panels (aluminum composite metal panels) are efficiently installed and securely fastened with this system, enhancing the overall appearance of the finish. The presence of Z bars may change building configurations but this makes it easier to install the ACM panels; its limits provide more support to the perimeter, however, in that regard, trim is more efficiently covered by E bars.

Male-Female Systems

This system employs the ‘Male-Female’ principle explained from the male perspective. In other words, the panels are designed to be 'screw-friendly,' allowing them to be securely fastened to adjacent panels without deviating from the expansion joint. The design of the panels is also meant to make it very easy to put them together and pull them apart. So, it is ideally suited for projects of a larger scale, such as those using 4x8 aluminum sheet metal or thin aluminum sheet metal for ease of assembly.

Riveted Systems

In the riveted system, Omega aluminum profiles are supported with pairs of specially crafted T spacers providing an interlocking system to stop mechanical movement and to support and fasten the ACM (aluminum composite material cladding) to the corner connections of the primary structural frame. This is because such structural systems have been deemed as having high levels of strength and robustness. Moreover, the hole rivet connections provide for the mechanical joining of the two panels, which means the panel will not even bulge regardless of the weather or any other external conditions.

Glued Systems

The glued system is designed for use in buildings requiring internal applications, incorporating deformable elements such as angular spacers and wavy tubes. Such a system is most preferred in cases where no interruptions in the assemblies or structures are envisaged. This issue is easily resolved using the available adhesive, which forms a bond between the aluminum plate and the supporting structure, while also assisting with rib alignment through the aid tubes. This system is ideal for aluminum sheet metal material applications where a seamless finish is desired.

Tell Us About Your Next Project

Interested in optimizing your design with ACM cladding? Tell us about your project, and our team will offer a comprehensive consultation. We’ll evaluate your design and propose standard, modified, or custom-engineered solutions to achieve your desired outcome.

Partner with Manaco

Our Aluminum Composite Metal Panel Process at Manaco

01 /

Consultation

We come together to understand what your project requires. This is achieved through various methods, including discussing the different types of composite panels available in Canada, advanced 3D design techniques, estimating the required quantity, determining costs, and outlining the timeline for completion.

02 /

Design and Shop Drawings

Agreement of shop job and working drawings is made with your expert specifications. Nonetheless, this point includes the quality or the sharpness of the task yet to be performed.

03 /

Fabrication

After the approval of the shop drawings, the project moves into fabrication where our skilled workers form the ACM panels with great detail for the installation of mounting system elements aligned in every corner.

04 /

Installation

Finally, the flawless application of the ACM panels is done by our seasoned staff, which wraps up by giving an appearance that is attractive and most importantly long-lasting to the building.

Since the 1980s, due to increased complexity in building, the architecture profession has evolved suggesting a different image of the field beyond aesthetics and design of structures.

300

Successful Projects

100

Partnerships with industry leaders

2.8m

Square Feet Built.

1 Orlon Cres.

20 Palomino Cres.

479 Lytton Blvd

453 Hounslow Ave

174 Hendon Ave